Mechanical Engineering Intern @ RPD, LLC

Published:

Non-Disclosure Agreement: I’ve included only shareable highlights; proprietary info stays under wraps.

I interned at RPD, LLC, a stealth-based engineering consulting firm supporting top-tier clients across defense, medtech, consumer, and B2B manufacturing industries, including Medtronic, CooperSurgical, SPI, and Cleanflame, as well as multiple startups. Over the course of my internship, I had the opportunity to own mechanical design and validation efforts for diverse client programs, driving products from ideation through to high-volume production.

Key Contributions

-

Led design and validation for 5+ client programs, supporting NPI from concept to production (50K–100K+ units annually).

-

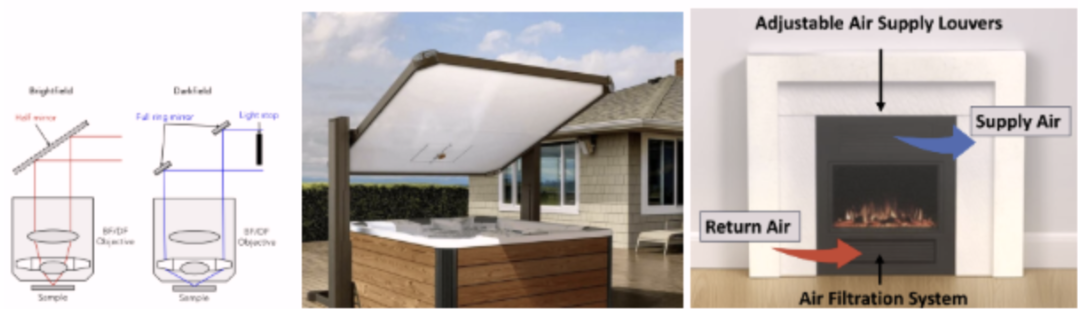

Developed a chip-on-glass LED illumination module for biosafety cabinets. Achieved 78% improvement in thermal dissipation and simplified assembly, enabling cost-efficient scaling.

-

Designed and fabricated test fixtures for V&V, reducing setup time and ensuring repeatable testing.

-

Engineered a new lift mechanism for a jacuzzi system capable of reliable operation in harsh, snowy conditions.

-

Conducted failure analysis on SLA 3D printers, identified recurring defect root causes, and implemented countermeasures that minimized downtime and saved significant prototyping costs.

-

Negotiated with U.S. manufacturers to avoid tariffs, cutting launch timelines by 80% and reducing part costs by 25% through rapid DFMA iterations and supplier coordination.

-

Created detailed 2D prints with GD&T, supported design reviews, DFMA reviews, supplier meetings, and stakeholder presentations.