Vehicle Quality and Engineering Intern @ Kia India Pvt. Ltd.

Non-Disclosure Agreement: I’ve included only shareable highlights; proprietary info stays under wraps.

Interned at Kia India during the launch of the India-specific Kia Carens at a high-capacity plant producing over 300,000 vehicles annually. Partnered with cross-functional teams to deliver rapid quality improvements across multiple vehicle programs during ramp-up.

Drove resolution of a critical tailgate water ingress issue on the Kia Carens using structured problem-solving (SPC, 7 QC tools, fishbone analysis). Executed geometry redesigns to the weatherstrip, tailgate mounting points, drip channel layout, and weld locations. Achieved a defect rate reduction from 62% to 0%, validated through leak and statistical testing.

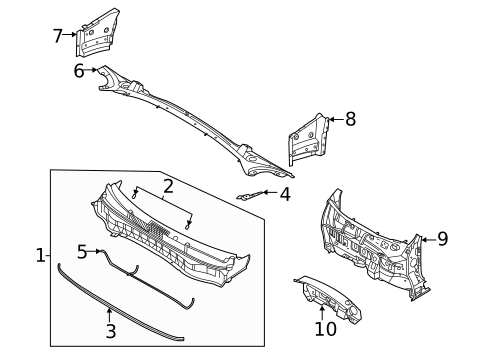

Optimized the cowl assembly on the Kia Seltos, improving ergonomics and reducing assembly time by 40%, which enhanced cycle time and key production KPIs including line efficiency and throughput.

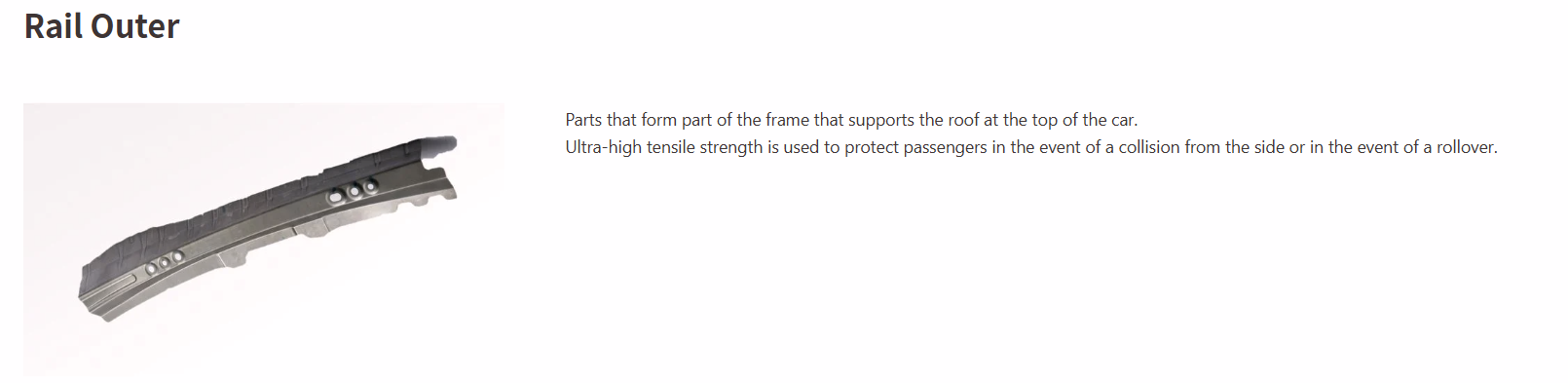

Boosted First Time Yield by over 70% and contributed to higher OEE by driving die corrections, supplier process improvements, and robust validation loops.