Control Arm Design & Structural Evaluation

Date:

Overview

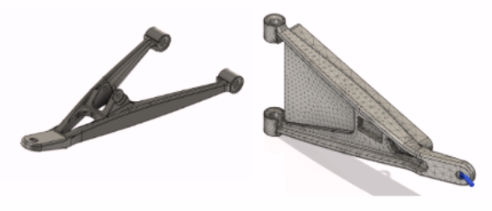

I designed a control arm inspired by outdoor ATV applications, where durability and stiffness are critical. Since control arms in vehicles must be very stiff and not act like springs, I set the performance expectation to deflections in the tenth-of-a-millimeter range.

Methodology

-

Created the CAD model and set up multiple load cases in Fusion 360.

-

Applied forces (multiple load cases) at the ball joint and constrained the bushings.

-

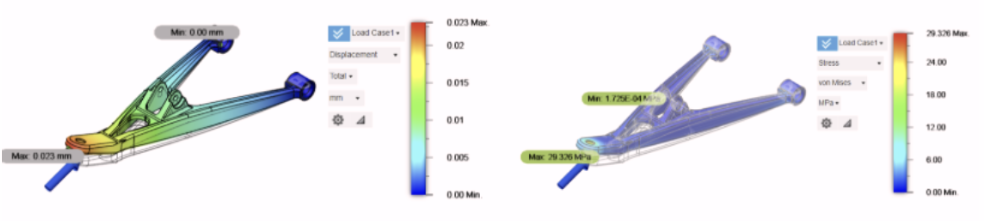

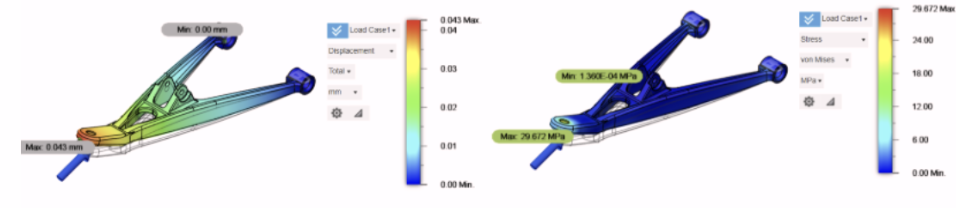

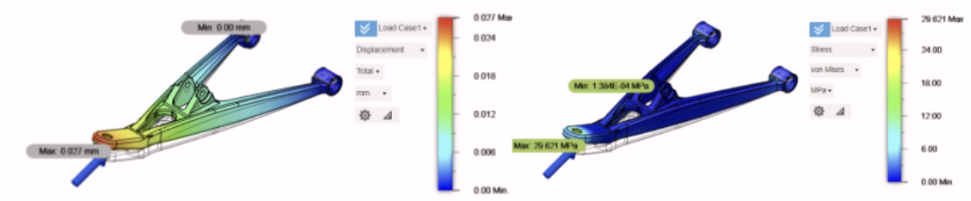

Compared three widely used materials: Aluminum 6061-T6, Hot-Formed Steel DP600, and Carbon Fiber Reinforced Polymer (CFRP).

-

Evaluated each case for displacement, von Mises stress, mass, and safety factor.

Results

CFRP: Achieved the best performance, combining lowest mass, high stiffness, and safe stress levels.

Aluminum 6061-T6: Delivered a balanced outcome, with good weight savings but higher deflection than CFRP.

Steel DP600: Proved structurally safe with the least deflection, but at the cost of being the heaviest and least weight-efficient.

My Take:

-

Weight-critical / EV & performance focus - CFRP

-

Balanced cost & manufacturability - Aluminum 6061-T6

-

Cost / robustness where weight is secondary - DP600 steel